I purchased a slightly toasted AH4 tuner, which had clearly been overloaded during the tune cycle.

The power attenuator had been thoroughly cooked.

I spent a couple of afternoons removing the burnt area of the PCB using a high speed rotary tool. then I re built the missing PCB using fiberglass matting and epoxy resin. Finally I made new PCB traces from copper foil to allow new attenuation resistors to be added.

Sadly there was nothing to see on the top side of the board – Just a big black charred mess. This is the back of the board that gives a clue.

This is the board after the charred area was removed, resin applied and new tracks cut out.

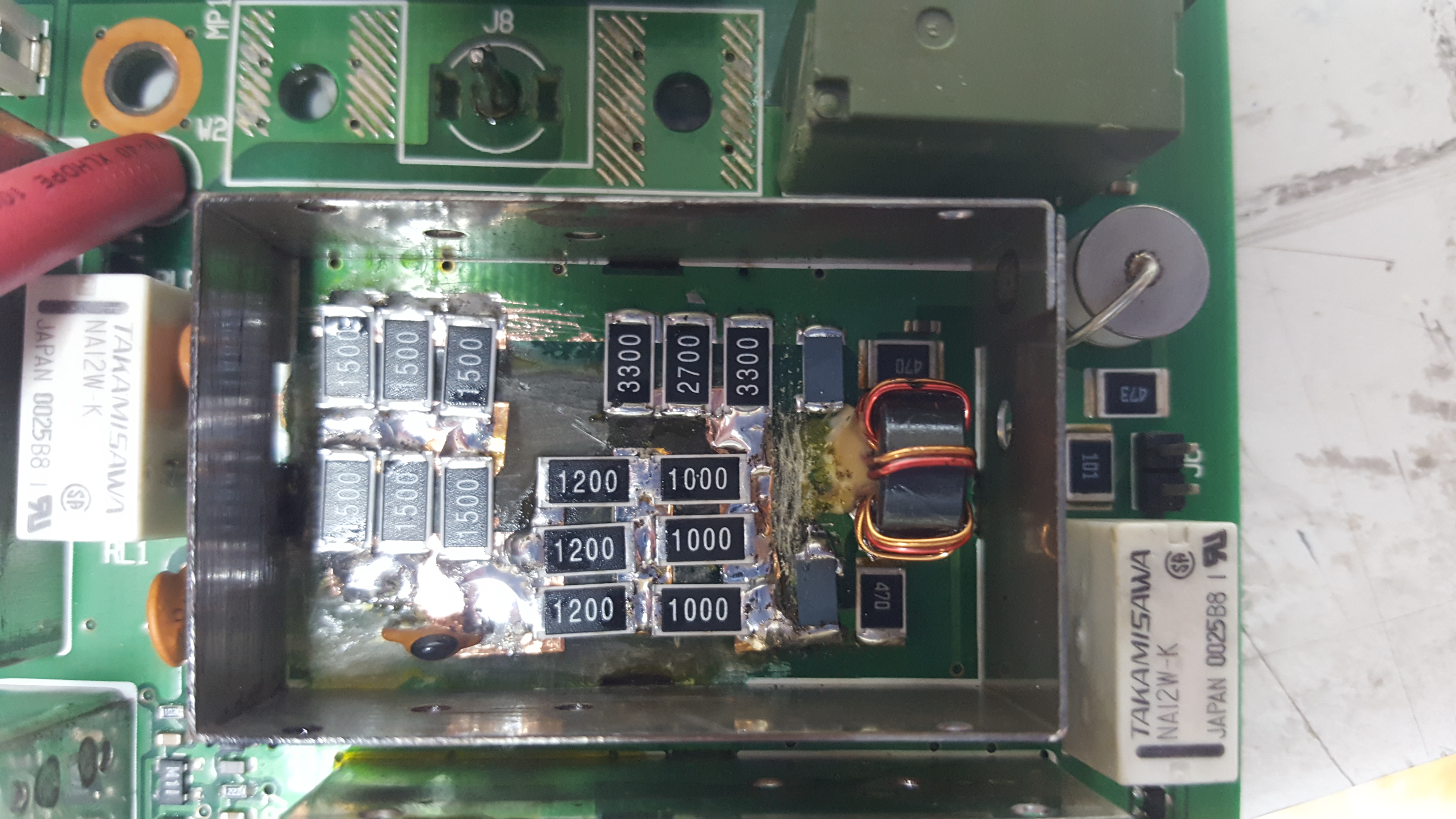

This is the repair after adding new components.

And finally – A reference photo that shows what it should have looked like before it was cooked.

After the repair, I followed the alignment instructions in the service manual. It works like a charm. Another piece of gear saved from the scrapheap.

Thanks for that – really worthwhile information